RONART NEWSLETTER

It has been over a year since our last newsletter and February seems a good time to think of things to do for the new spring and summer or plans for next year. Perhaps some open air motoring could be just the solution!

IN THIS ISSUE

- ALUMINIUM BODYWORK

- W152 PROPORTIONS AND SIZE

- NEW ADJUSTABLE PEDALS option

- RONART FABRICATION WORKSHOP 2020

- V12 ENGINE and JENVEY FUEL INJECTION

- CHASSIS TALK

- DANI LARI - MAGICIAN AND ILLUSIONIST - a full size W152 on the stage

- CARS FOR SALE

RONART W152 V12

See a 360 video of a Ronart 5.3 litre V12 in British Racing Green. Click Here

ALUMINIUM BODYWORK

THE W152 is also available in aluminium body version or part aluminium. Recently two bespoke bonnets have been made and the pictures show a bonnet being manufactured in November for a V12 car in Norfolk. The louvres being stamped out give a very nice visual effect on the W152.

The W152 is also available with part alloy or full alloy options

The part alloy option has the main monocoque in GRP complete with bulkheads and safety rollcage. The tubular rollcage is pre-bonded and jigged with the rollover bar integrated within the headrest. This forms part of the rear rollcage structure which extends to provide side impact and front scuttle roll cage protection. The rollcage also provides the outer and upper seatbelt anchorage points. The engine bulkhead and pedal area are fitted with alloy panels.

The interior of the cockpit also has alloy panels fitted to most of the visible interior including tunnel, floor and side sections. The center monocoque body is easily fitted or removed by two people within minutes and the remaining panels easily fitted allowing for very easy access for building the car.

The alloy bonnet sides and alloy bonnet feature lots of louvres, which may be tailored to customer/engine requirements. The V12 can have four rows/sets of louvres just in the bonnet!! The nose cone and rear tail section are supplied in composite. The alloy wings have nice rolled edges and with steel wing stays.

The full alloy option has the centre cockpit, tail section and nose in aluminium alloy.

W152 Proportions and Size.

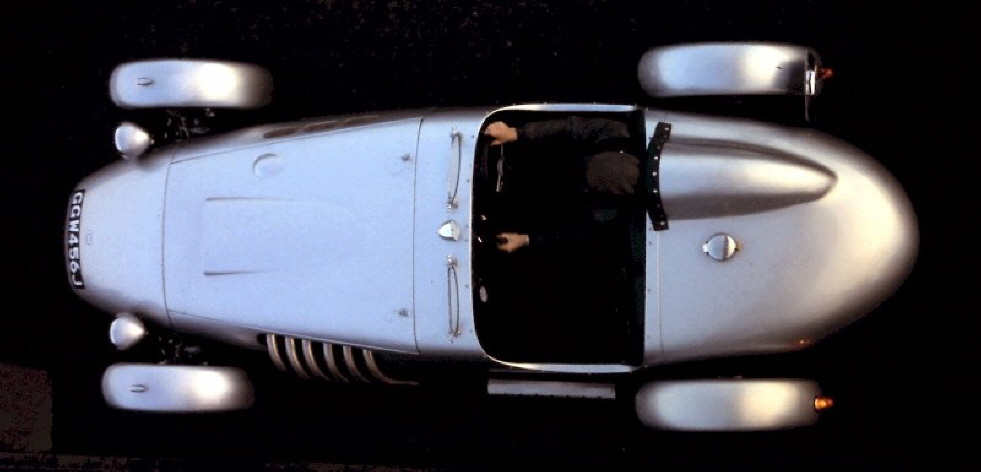

Many people who have not seen a W152 close up do not realise the sheer size of the car. These pictures were taken in 1986 and show the proportions of the long wheelbase and width of the car compared to the 5'8" tall driver. The car has the same wheelbase 109" as the Jaguar XJ6/S. (Only the wheels are 3" wider front and rear due to the knockon wire wheels)

Driver position-wise you are actually sitting in the rear seat position of the original car!!!. The engine is situated three feet further centrally in the chassis which helps give the W152 excellent weight distribution front to rear of 48/52%. These proportions help give the W152 unique presence on the road and a driving experience to be enjoyed again and again.

Pick a nice warm sunny day and just head out on some nice winding roads……..

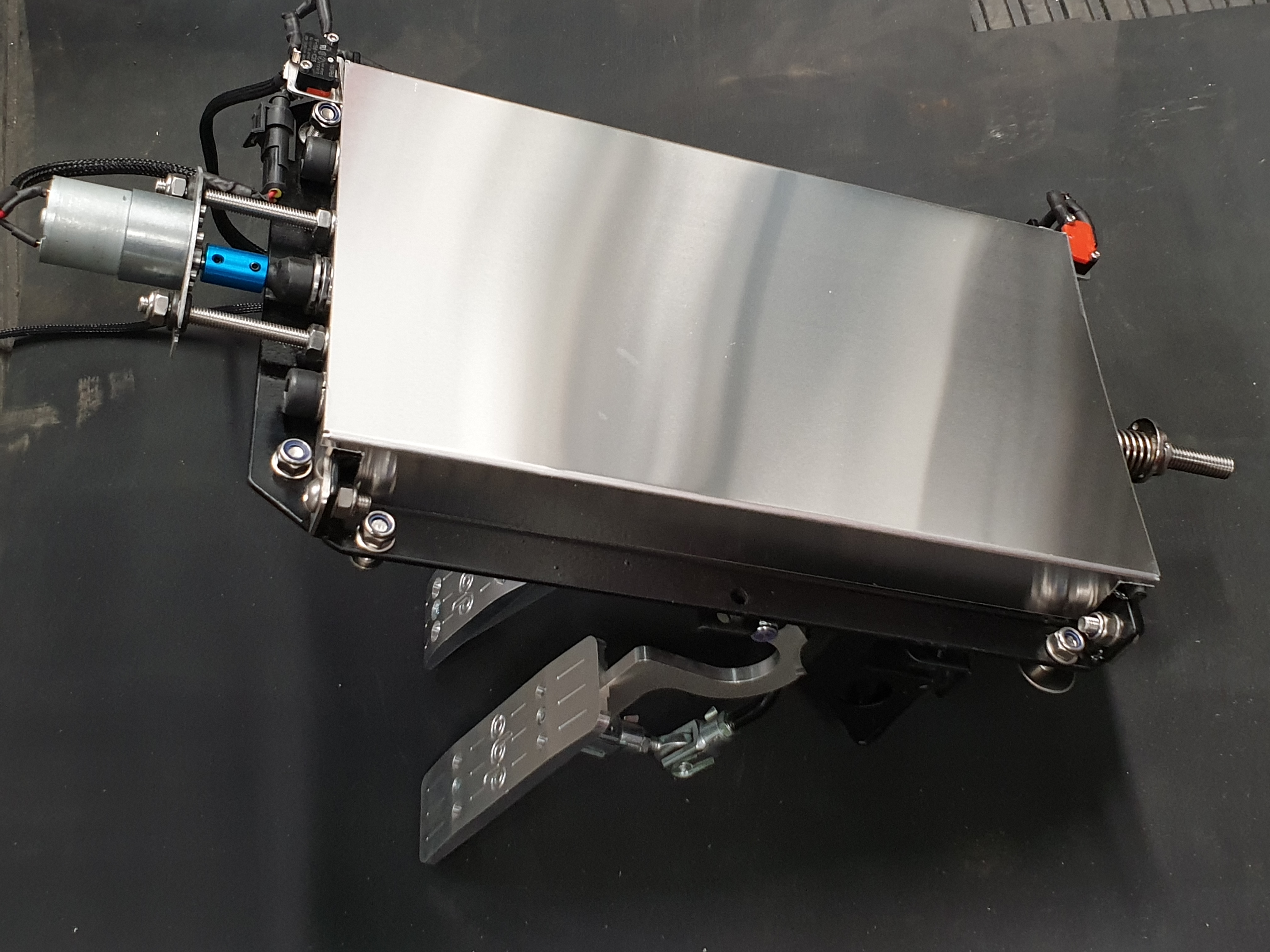

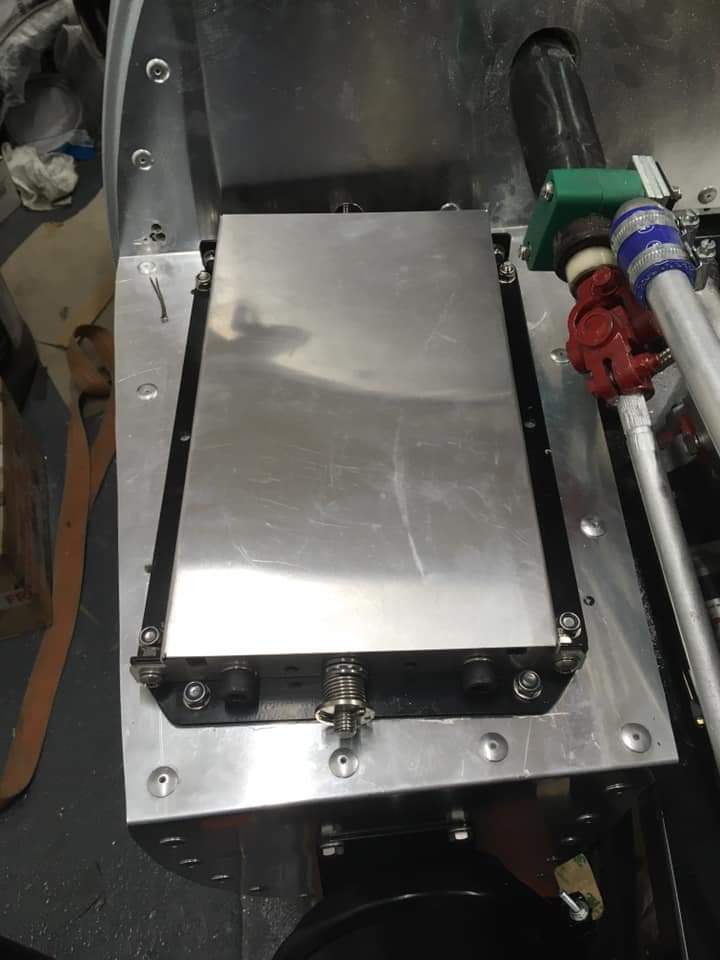

ADJUSTABLE PEDALS – manual and electrically operated

We have been working on a new pedal box system which allows the very latest alloy pedals to be moved forwards or backwards. The standard version of this adjustable pedal box allows for manual adjustment via a rotary knob fitted under the dashboard within reach of the driver.

There also is an electrically operated option which features a switch on the dashboard which controls a module and activates the movement of pedals by electrical motor. A buzzer sounds when the limits have been reached and it automatically stops the movement until the switch is changed to the opposite direction. As an extra measure, the buzzer is accompanied by an LED indicator. Six "aeroquip" stainless hoses connect the pedal box to the usual brake pipes and this allows the flexibility of movement.

The pedal box can quickly be altered to suit drivers of different height and leg length. The W152 also uses the safety collapsible Jaguar steering column which has the ability to have the steering wheel adjusted towards the driver. Having the pedals and the column adjustable allows the driving position to be altered quickly if the drivers are changed and they require a different height/reach.

The unit is only 45mm in additional height above the pedal box and sits neatly on top of the bulkhead cockpit footwell.

The pedals have been CNC machined out of aluminium alloy and come with adjustable pads which can alter both the height and the lateral spacing. For the more spirited motorsport track days an option, is that the balance bar system may be altered in the cockpit by a remote mechanism controlled by a rotary knob which can change the bias setup front to rear of the cars braking performance.

RONART FABRICATION WORKSHOP 2020

This is where all of the fabrication, forming and welding of the W152 chassis and components are made. The facility includes MIG, TIG and ARC welding, pneumatic/hydraulic tube bender, end mill, cut off saws, bandsaw, sheet metal folder, metal sheet rolls, flypress, hydraulic press, polishing machines, vacuum pump as well as pedestal drills and other equipment. Both single and three phase equipment are used.

The jigs are in green and the main chassis jig is shown, this has numerous secondary jigs which bolt on to the main jig to ensure repeatability and accuracy of manufacture of the W152 chassis.

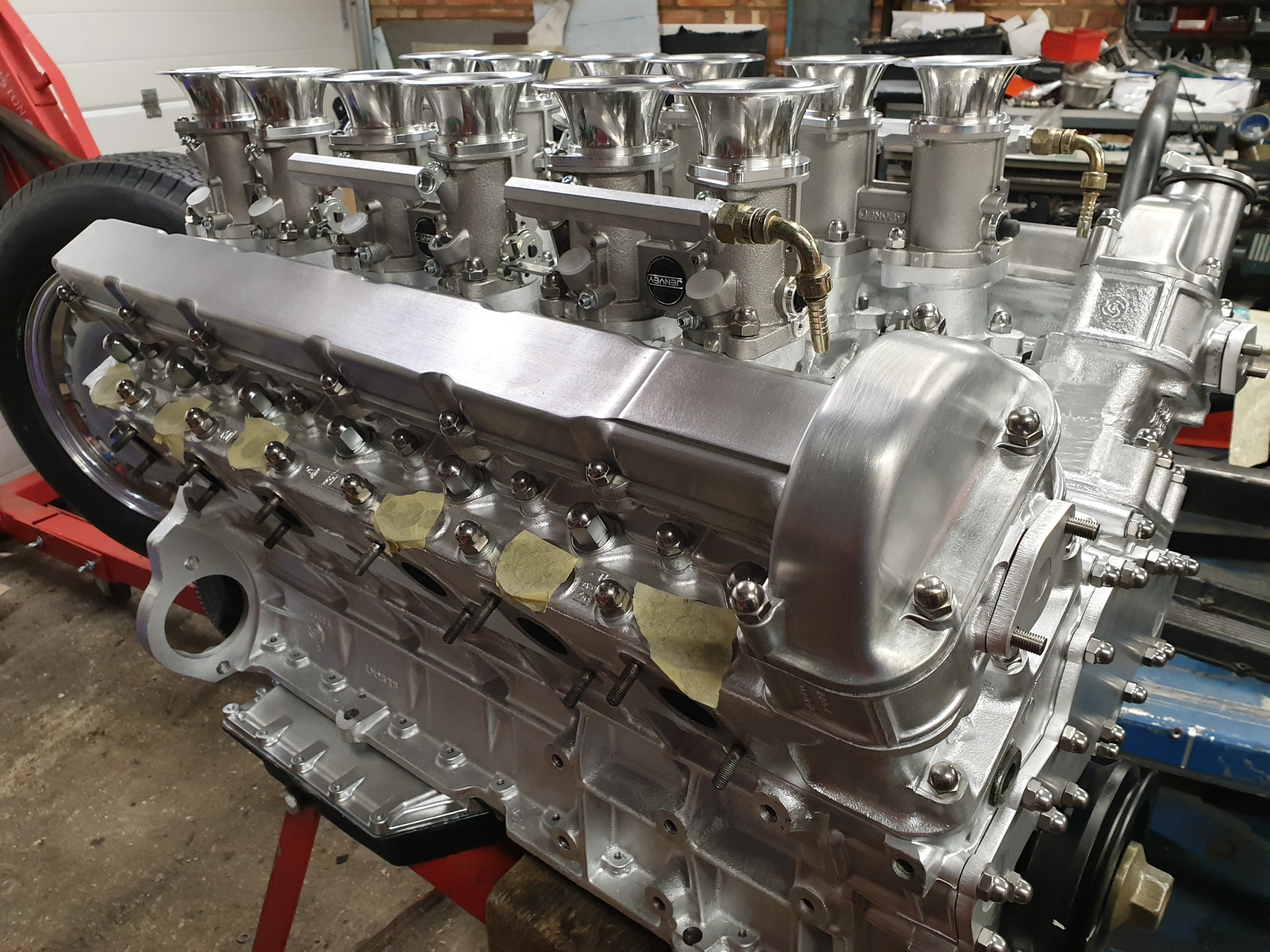

V12 ENGINE with FUEL INJECTION SYSTEM

Recent V12 engine developments have led to a number of enhancements we can offer the owner for his build. We can finish the build of both 6 cylinder and V12 engines to your specification of fitment and finish.

The pictures show a V12 in the process of being built with individual manifolds and modern fuel injection system.

- Full EFI fuel injection system with independent alloy manifolds, these are modified weber manifolds which when separated look very individual and purposeful.

- Emerald ECU and wiring allows for control of engine management and also controls the water pump, the cooling fan and a number of other functions. It also features a switch-controllable fuel injection which the driver can select between economy and sport operation, excellent for changing characteristics of motorway cruising and spirited track-day use.

- The crank needs to have a crank sensor which accurately gives the position of the cyclic firing position and this is mounted on a plate/bracket allowing for position control. (Not fitted in the pictures.)

- Stainless steel domed nuts for heads, rocker covers, plates and manifolds

- Lasercut aluminium alloy water plate with water pipe fittings and a brushed finish

- Water pump alloy plate specifically for electric water pump for high power engines

- Oil breather aluminium alloy plates

- Central Vee aluminium alloy plate brushed finish

Notes on the above engine:-

These adaptions and modifications are available for your V12 engine either as a kit or built in our workshop.

CHASSIS TALK

Back in 1996 Ronart were the first in the small specialist car industry to submit the MK2 chassis to a hydrapulse test at Manchester University. This tested the design and manufacture of the chassis by using hydraulic rams controlled by software to effectively age the chassis by 100,000 miles within two weeks. This was a continuous 24hr operation and was quite severe.

One of three types of test led to the wheel being moved in a vertical direction which was so severe that the sidewall of the tyre was broken and the shock absorber had to be water cooled with an 8 gallon water jacket cooling system.

The second type of test moved the wheel in a horizontal direction whilst the third compressed and stretched the wheel in and out. At the end of the test the chassis was inspected and crack-tested for integrity and after witnessing the punishment in action I was very relieved when it passed A1.

Afterwards in 1996 we also carried out seatbelt anchorage testing to EEC standards as witnessed by a government agent and this test had huge chains mounted on all of the rollcage and chassis seatbelt bushes. A force of 6 tonnes was applied and the car inspected for deformation and integrity. Once again the test passed A1 and we were pleased with the result.

We are now building the 2021 W152 chassis, roll cage and ancillary parts. Just the steel parts alone require over 120 CAD lasercut parts, numerous machined parts, together with over 30 metres of tube, all welded or formed into making the steel parts for a car.

It is far from the typical ladder frame chassis commonly found in old style sports cars.

The Ronart W152 is a multitubular spaceframe backbone chassis with a track record of over 30 years in manufacture.

The design incorporates a low centre of gravity, excellent front to rear weight distribution and excellent torsional rigidity and it is considered one of the best in the industry.

Whilst the W152 is available mainly in component form it is available as a part built car with the remaining completion to be carried out by the owner. The suspension castor, camber and toe-in are all set up ready to go. The donor parts can be supplied to us or additionally we can source these components for you.

Supply us with the engine and we will fit this for you as seen in the above photograph. The bodywork is fitted to the car prior to delivery. The remaining parts are supplied for you to complete.

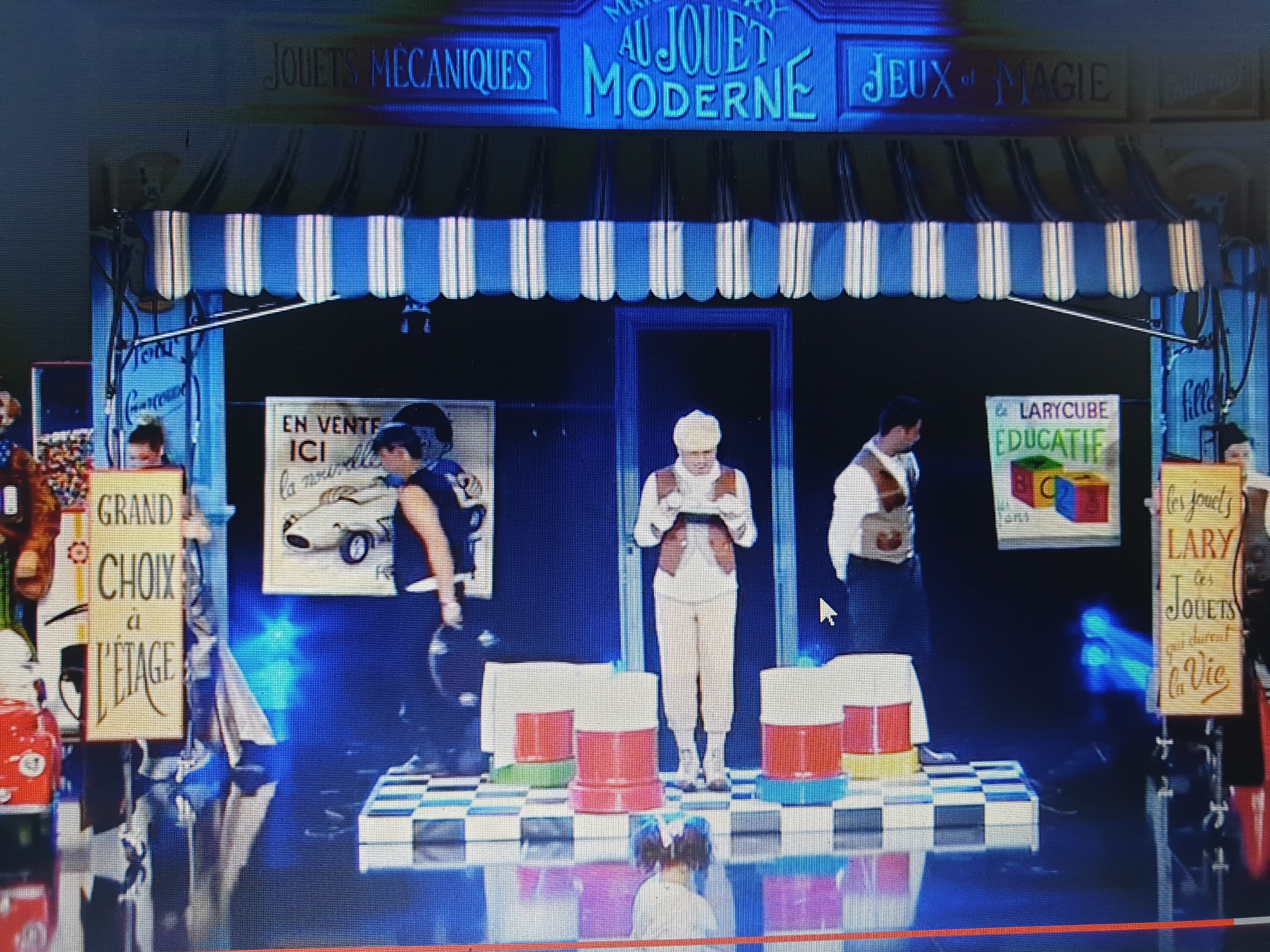

DANNY LARI MAGICIAN ILLUSIONIST – RONART ON STAGE

See a Ronart appear on stage by magic, courtesy of the famous French Magician Illusionist Dani Lari, click on the following link to see his stage show featuring a W152 S6.

CARS FOR SALE

W152 S6

Two cars are coming up for sale in the next three months. If you would like advance notice of these before we put them up on our website please let me know.

Both of these cars are S6, one a MK1 and the other an early MK2. The MK2 has only 1500 miles and is fitted with almost every option and is in immaculate condition having been stored in controlled climate since new. Other cars do come up from time to time but are usually snapped up quickly since not many W152's come up for sale.

If you would like to be notified in advance of public notices of imminent cars for sale please email me to put you on our sales notification list.